Platinum (Pt) is a rare and valuable metal that is widely used in various industrial applications due to its unique properties. Platinum ore refers to the naturally occurring rocks or minerals that contain significant concentrations of platinum, usually in the form of platinum group minerals (PGMs) and associated minerals. Platinum ore is typically found in specific geological formations and is extracted through mining and extraction methods. The geology, formation, and distribution of platinum ore are complex and varied, and platinum mining and production have significant economic, environmental, and social implications. This introduction will provide an overview of platinum ore, including its properties, uses, and significance in various industries, as well as an overview of the geology and formation of platinum ore deposits, mining and extraction methods, global distribution, and environmental and social impacts associated with platinum mining.

Brief overview of platinum’s properties and uses

Platinum (Pt) is a precious and rare metal with unique properties that make it highly valuable and sought after in various industrial applications. Here is a brief overview of platinum’s properties and uses:

Properties of Platinum:

- Platinum is a dense, malleable, and ductile metal with a silvery-white color.

- It has a high melting point of 1,768 degrees Celsius (3,214 degrees Fahrenheit), making it resistant to high temperatures.

- Platinum is highly resistant to corrosion, tarnish, and wear, making it suitable for use in harsh environments.

- It is an excellent conductor of electricity and has catalytic properties, making it useful in various chemical reactions.

Uses of Platinum:

- Catalytic converters: Platinum is used as a catalyst in catalytic converters to reduce emissions from vehicles, converting harmful gases into less harmful ones.

- Electrical and electronic applications: Platinum is used in electrical contacts, spark plugs, and various electronic components due to its excellent electrical conductivity.

- Jewelry: Platinum is used in jewelry due to its rarity, durability, and lustrous appearance.

- Chemical and petroleum industry: Platinum is used as a catalyst in various chemical and petroleum refining processes.

- Medical applications: Platinum is used in medical devices, such as pacemakers, as well as in cancer treatment drugs.

Platinum’s unique properties and diverse range of uses make it a highly valuable and important metal in various industries, contributing to its significance in the global economy.

Platinum Minerals

Platinum (Pt) minerals refer to the naturally occurring minerals that contain platinum as a major component or as part of the platinum group minerals (PGMs). Platinum is a rare element in the Earth’s crust, and it typically occurs in small concentrations in certain types of rocks and deposits. The primary minerals that are associated with platinum ore are known as the platinum group minerals (PGMs), which include platinum, palladium, rhodium, iridium, osmium, and ruthenium. These minerals often occur together in nature and are collectively referred to as PGMs due to their similar chemical and physical properties.

Some of the common platinum minerals include:

- Sperrylite (PtAs2): This is the most common platinum mineral and is composed of platinum and arsenic. It is typically found in nickel-copper sulfide ore deposits.

- Cooperite (PtS): This is a platinum sulfide mineral that is often found in association with other platinum minerals in ultramafic rocks.

- Braggite ((Pt,Pd,Ni)S): This is a platinum, palladium, and nickel sulfide mineral that is commonly found in layered intrusions and ultramafic rocks.

- Platarsite (PtAsS): This is a platinum arsenic sulfide mineral that is found in association with other platinum minerals in some platinum ore deposits.

- Michenerite (PdBiTe): This is a palladium bismuth telluride mineral that is often found in association with platinum minerals in some platinum deposits.

- Spinel group minerals: Some minerals from the spinel group, such as chromite (FeCr2O4), can also contain trace amounts of platinum.

It’s worth noting that platinum minerals often occur in complex and varied geological settings, and the exact mineralogy of platinum ore deposits can vary depending on the specific geology and formation conditions. Proper identification and characterization of platinum minerals are crucial in the exploration, mining, and processing of platinum ore deposits.

Geology and Formation of Platinum Ore

Geology and formation processes of platinum ore are complex and typically involve unique geologic settings and mineralization processes. Here are some key points that can be included in a discussion on the geology and formation of platinum ore:

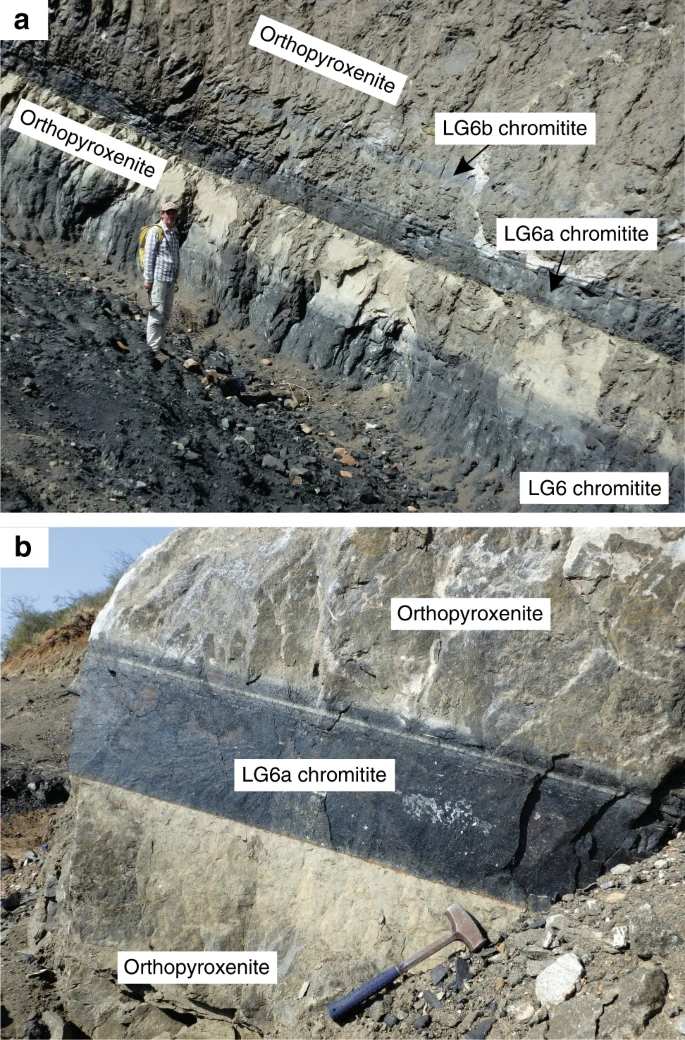

- Geologic settings: Platinum ore deposits are commonly associated with ultramafic rocks, which are high in magnesium and low in silica. These rocks include peridotite, pyroxenite, and dunite, and are typically found in areas of ancient continental crust or in ophiolite complexes.

- Tectonic processes: Platinum ore deposits are often formed through tectonic processes, such as subduction and collision of tectonic plates. Subduction zones, where one tectonic plate is being pushed beneath another, can create conditions for the formation of platinum-rich magma chambers and subsequent ore deposits. Collision zones, where two tectonic plates are coming together, can also result in the formation of platinum ore deposits through processes such as crustal melting and magma emplacement.

- Magmatic processes: Platinum ore deposits are primarily formed through magmatic processes. Platinum-rich magmas are generated in the Earth’s mantle and are transported to the crust through processes such as magma ascent, emplacement, and crystallization. During these processes, platinum and associated minerals can separate from the magma and accumulate in specific zones, forming platinum ore deposits.

- Hydrothermal processes: Hydrothermal processes can also contribute to the formation of platinum ore deposits. Hydrothermal fluids, which are hot, mineral-rich fluids that circulate in the Earth’s crust, can interact with existing rocks and minerals, resulting in the mobilization and concentration of platinum and associated minerals in specific areas.

- Secondary processes: Platinum ore deposits can also form through secondary processes, such as weathering, erosion, and sedimentation. In some cases, platinum minerals can be transported by rivers, streams, and other natural processes, and then concentrated in placer deposits, where they can be economically extracted.

Understanding the geology and formation processes of platinum ore is crucial for exploring and exploiting platinum resources effectively. It involves a combination of geologic mapping, geochemical analysis, geophysical surveys, and other exploration techniques to identify and evaluate potential platinum ore deposits.

Latypov, R., Costin, G., Chistyakova, S. et al. Platinum-bearing chromite layers are caused by pressure reduction during magma ascent. Nat Commun 9, 462 (2018). https://doi.org/10.1038/s41467-017-02773-w

Types of platinum ore deposits

There are several types of platinum ore deposits that can be categorized based on their geologic characteristics and formation processes. Some common types of platinum ore deposits include:

- Bushveld Complex-type deposits: These are the most significant type of platinum ore deposits and are located in the Bushveld Complex in South Africa. They are large layered mafic to ultramafic intrusions that contain platinum, palladium, rhodium, and other platinum group elements (PGEs). These deposits formed through multiple stages of magmatic processes, including magma chamber formation, fractional crystallization, and magma mixing.

- Norilsk-type deposits: These are located in the Norilsk-Talnakh region of Russia and are associated with mafic to ultramafic intrusive complexes. They are characterized by high grades of platinum, palladium, and other PGEs, and are believed to have formed through a combination of magmatic processes, such as magma chamber formation and fractional crystallization, as well as hydrothermal processes.

- Merensky Reef-type deposits: These are located in the Bushveld Complex in South Africa and are characterized by a specific layer or reef of platinum-rich ores within the layered mafic to ultramafic intrusions. The Merensky Reef is a thin layer of platinum-bearing sulfide minerals that formed during the solidification of the magma chamber and subsequent crystallization processes.

- Ural-Alaska-type deposits: These are located in the Ural Mountains of Russia and in Alaska, USA, and are associated with mafic to ultramafic intrusions. They are characterized by the occurrence of platinum, palladium, and other PGEs in sulfide minerals, and are believed to have formed through magmatic processes, such as fractional crystallization and magma mixing.

- Placer deposits: These are secondary deposits where platinum and associated minerals are transported by rivers, streams, and other natural processes and then concentrated in specific areas, such as river beds or alluvial deposits. Placer deposits can be found in various regions around the world and are typically formed through weathering, erosion, and sedimentation processes.

These are some of the common types of platinum ore deposits. The geologic characteristics and formation processes of platinum ore deposits can vary depending on the specific location and geologic setting, and understanding these differences is important for exploration, mining, and extraction of platinum resources.

Mining and Extraction of Platinum Ore

Mining and extraction of platinum ore typically involve several steps, including exploration, mine development, ore extraction, ore processing, and refining. Here is a general overview of the process:

- Exploration: Platinum ore deposits are typically located through geologic mapping, geophysical surveys, and geochemical sampling. This involves identifying areas with the potential for platinum mineralization based on geologic characteristics, such as rock types, structures, and mineral associations.

- Mine Development: Once a promising platinum deposit is identified, mine development begins. This involves clearing vegetation, constructing access roads, and developing infrastructure, such as mine shafts, tunnels, and ventilation systems, to access the ore deposit.

- Ore Extraction: Platinum ore is typically extracted using underground mining methods, such as mechanized mining, cut-and-fill mining, or room-and-pillar mining, depending on the specific deposit characteristics. Ore is extracted from the deposit using various mining equipment, such as drills, loaders, and haul trucks.

- Ore Processing: Once the ore is extracted, it is transported to a processing plant for further processing. Platinum ore is typically processed through a series of crushing, grinding, and flotation steps to separate the valuable platinum minerals from the gangue minerals. Additional processes, such as gravity separation, magnetic separation, or smelting, may also be used depending on the specific ore characteristics and desired platinum concentrate.

- Refining: After the platinum concentrate is obtained, it is further processed through refining processes to obtain high-purity platinum. Refining processes typically involve chemical and/or electrochemical methods, such as solvent extraction, precipitation, or electrolysis, to remove impurities and obtain platinum in its pure form.

- Product Distribution: Once the platinum is refined, it is typically sold to end-users, such as jewelry manufacturers, automotive industries, electronics industries, and other industrial applications.

It’s important to note that the specific mining and extraction methods, as well as the processing and refining techniques, can vary depending on the type of platinum ore deposit, its grade, and its location. Additionally, environmental and social considerations, as well as regulations and laws related to mining and extraction, need to be taken into account to ensure responsible and sustainable mining practices.

Global Distribution of Platinum Ore

Platinum ore deposits are relatively rare and are found in limited geographic locations around the world. The majority of the world’s platinum production comes from a few countries, with the largest reserves and production occurring in South Africa, Russia, and Zimbabwe. Here is a brief overview of the global distribution of platinum ore:

- South Africa: South Africa is the largest producer of platinum in the world, accounting for approximately 70-80% of global platinum production. The platinum deposits in South Africa are primarily located in the Bushveld Complex, a layered mafic to ultramafic igneous complex in the northern part of the country.

- Russia: Russia is the second-largest producer of platinum, with significant deposits located in the Norilsk-Talnakh region of Siberia. These deposits are associated with the Norilsk-Talnakh nickel-copper sulfide ore deposits and are among the largest platinum reserves in the world.

- Zimbabwe: Zimbabwe is another significant producer of platinum, with deposits located in the Great Dyke, a geological feature that runs north-south through the country. The Great Dyke is a layered mafic to ultramafic complex that contains platinum, palladium, and other valuable minerals.

- Other countries: Platinum ore deposits are also found in smaller quantities in other countries, including Canada, the United States, Australia, and Colombia, among others. However, the production from these countries is relatively small compared to the major producers mentioned above.

It’s important to note that platinum deposits are often found in association with other minerals, such as nickel, copper, and palladium, and the geological and mineralogical characteristics of each deposit can vary. The mining and extraction methods, as well as the processing and refining techniques, can also vary depending on the specific deposit characteristics and location.

Platinum Production

Platinum production involves several stages, including mining, extraction, processing, and refining. Here is a brief overview of the typical steps involved in platinum production:

- Mining: Platinum ore is typically extracted from underground mines using various mining methods depending on the deposit characteristics. These methods may include conventional underground mining, mechanized trackless mining, or open-pit mining, depending on the depth, shape, and size of the deposit.

- Extraction: Once the ore is mined, it is typically processed to extract the platinum group metals (PGMs), which include platinum, palladium, rhodium, ruthenium, iridium, and osmium. This is usually done through a combination of crushing, grinding, and froth flotation, which separates the PGMs from the other minerals and impurities in the ore.

- Processing: After extraction, the PGM concentrate is further processed to remove impurities and to obtain a refined product. This may involve additional steps such as smelting, where the PGM concentrate is heated to high temperatures to separate the PGMs from other impurities, and refining, where the PGMs are further purified through chemical and electrolytic processes to achieve high levels of purity.

- Refining: Refining is a critical step in platinum production, as it involves the removal of impurities to obtain a final product with high levels of purity. Platinum refining may involve several stages of chemical and electrolytic processes to remove impurities such as base metals, sulfur, and other elements, and to achieve the desired level of purity for the final platinum product.

- Recycling: Platinum is a precious metal that is highly valued for its unique properties and applications. In addition to primary production from mining, platinum is also obtained through recycling of spent catalysts, jewelry, and other sources. Recycling of platinum helps to reduce the demand for primary production and conserve natural resources.

It’s important to note that the platinum production process can vary depending on the specific deposit characteristics, location, and technology used. Additionally, environmental and social considerations, such as sustainable mining practices, safety regulations, and community engagement, play an important role in modern platinum production.

Uses and Applications of Platinum

Platinum is a rare and valuable metal that is widely used in various industrial, automotive, and jewelry applications due to its unique properties. Some of the key uses and applications of platinum include:

- Automotive Industry: Platinum is used as a catalyst in automotive catalytic converters, which are essential components in modern vehicles to reduce emissions of harmful pollutants from exhaust gases. Platinum helps to convert toxic gases, such as carbon monoxide, hydrocarbons, and nitrogen oxides, into less harmful substances, contributing to cleaner air and reduced air pollution.

- Chemical Industry: Platinum is used as a catalyst in various chemical processes, including the production of fertilizers, pharmaceuticals, and specialty chemicals. Platinum’s high catalytic activity, stability, and resistance to corrosion make it ideal for many chemical reactions, enabling the production of a wide range of important products.

- Electrical and Electronics Industry: Platinum is used in various electrical and electronic applications, including electrical contacts, spark plugs, and electrodes. Platinum’s high electrical conductivity and resistance to corrosion make it suitable for use in demanding electrical and electronic environments.

- Jewelry and Luxury Goods: Platinum is a popular metal for high-end jewelry and luxury goods due to its rarity, durability, and attractive appearance. Platinum is known for its distinctive silvery-white color, luster, and resistance to tarnish, making it a preferred choice for fine jewelry, watches, and other luxury items.

- Medical and Dental Industry: Platinum is used in various medical and dental applications, including surgical instruments, implants, and dental crowns. Platinum’s biocompatibility, inertness, and resistance to corrosion make it suitable for use in medical and dental devices that come into contact with the human body.

- Energy Industry: Platinum is used in fuel cells, which are devices that convert hydrogen and oxygen into electricity and heat through electrochemical reactions. Platinum’s high catalytic activity and stability make it an important component in fuel cells, which are being developed as a clean and efficient alternative to traditional energy sources.

- Glass and Glassmaking Industry: Platinum is used in glass production, particularly for specialized glasses, due to its high melting point and resistance to corrosion. Platinum is used as a material for glass furnace electrodes and other components that are exposed to high temperatures and corrosive environments.

- Investment and Financial Markets: Platinum is also used as an investment metal and traded in financial markets as a precious metal, similar to gold and silver. Platinum is valued for its rarity, stability, and diversification benefits in investment portfolios.

These are just some of the many uses and applications of platinum. Due to its unique properties, platinum finds extensive use in various industrial, technological, medical, and luxury sectors, making it a highly valuable and sought-after metal.

Summary of key points about platinum ore

Here is a summary of the key points about platinum ore:

- Platinum ore refers to rocks or deposits that contain significant amounts of platinum, a rare and valuable metal with various industrial, automotive, jewelry, and other applications.

- Platinum is typically found in association with other minerals, such as sulfides of nickel, copper, and iron, in ore deposits known as platinum group element (PGE) deposits.

- Platinum ore deposits can form through various geological processes, including magmatic, hydrothermal, and placer deposits. Magmatic deposits are the most common type and are associated with layered igneous rocks such as the Bushveld Complex in South Africa and the Stillwater Complex in the United States.

- Mining and extraction of platinum ore involve complex and specialized processes, including underground mining, flotation, smelting, and refining. Platinum mining is predominantly carried out in a few countries, including South Africa, Russia, Zimbabwe, and Canada.

- Platinum ore deposits are relatively rare and are found in limited geographic locations, with the majority of global production coming from South Africa and Russia. Other countries with smaller platinum reserves and production include Zimbabwe, Canada, United States, and Colombia.

- Platinum production is primarily driven by demand from the automotive industry for catalytic converters, as well as other industrial, jewelry, medical, and investment markets.

- Platinum is used in a wide range of applications, including automotive catalytic converters, chemical processes, electrical and electronics industry, jewelry and luxury goods, medical and dental devices, energy production, glassmaking, and investment markets.

- Platinum ore is a valuable and strategic resource, and its mining, extraction, and processing involve significant technical, economic, and environmental considerations. Sustainable and responsible mining practices, including environmental protection and social responsibility, are important in the extraction and processing of platinum ore.

- Platinum is a precious metal with unique physical and chemical properties, including high melting and boiling points, excellent catalytic activity, resistance to corrosion and tarnish, biocompatibility, and rarity, which make it highly valuable and sought-after in various applications.

Overall, platinum ore is a valuable and important resource that plays a critical role in various industrial, technological, and economic sectors, and its mining, extraction, and use require specialized knowledge, technology, and environmental considerations.